In many ways, project management is a recent craft; but one that has learned a lot from the world of old manufacturing processes. And project managers are constantly finding ways to implement the knowledge and experiences of 20th-century manufacturing to contemporary project management. With that in mind – lean project methodology is a great example!

Lean was born on the factory floor and that’s why it is often referred to as a manufacturing technique or strategy. However, that’s a bit incomprehensible because every process from service to production can benefit from a lean approach. That is the very reason why lean methodology is easily finding a home in almost every industry from banking to healthcare.

Taking a few pages out of the book of lean manufacturing, we’ll have a look at what exactly is the lean methodology and lean project management. Following that, we’ll also see the benefits of lean project management in the modern project-oriented workplace.

About Lean Project Management

Lean project management is a logical process used in manufacturing, that can be boiled down to two simple goals: minimizing waste while maximizing value. Indeed, using this methodology properly – in concert with modern project management software – ensures that there will be no waste to be found in your projects. At the same time, you can increase your profit margins while also achieving greater customer satisfaction!

Origins of Lean Management

In order to understand the lean project management principles, one must first understand the origins of this project management methodology. With that in mind, we venture all the way back to 1973.

Many first-world countries were shocked by the sky-rocketing oil prices; which was the result of a political dispute between Arab countries and Israel. At this time, many manufacturing companies dependent on petroleum (and all of them were, to some degree) report significant losses; many of them being forced to shutter their doors.

One of the countries particularly vulnerable to the rising oil prices was Japan; thus, a huge number of their companies faced significant issues due to the sudden inflation of these expenses. However, there was one company that proved to be a significant exception – Toyota. And this wasn’t a random fluke either.

The early-70s success of Toyota happened because of the long-standing principles of this company; the principles we recognize as lean management today.

At the end of WWII, the founders of Toyota led the company in accordance with the set of guidelines they dubbed the Toyota Production System. And this is basically the holy book of lean management.

These principles put the Toyota employees on a never-ending journey of improvement and inefficiency reduction in their work process. Thus, they were able to reduce the costs and lead-time in their manufacturing process, while also improving product quality and the satisfaction of their customers.

And thus, through the automobile industry, lean management was introduced into the western world of manufacturing theories. The waste elimination that Toyota managed was so undeniable, that it managed to lure all industries towards a lean management way of thinking; something that goes against pure mass production.

What is Lean Methodology?

The lean methodology can be divided into three parts: Lean Six Sigma Project Management, Deming Cycle, and Kanban. Let’s check out the three methodologies.

Lean Six Sigma is all about identifying the cause and reasons behind the problems in the project management process. This helps in the efficient use of resources and time. An acronym DMEDI is associated with Lean Six Sigma which refers to Define, Measure, Explore, Develop, and Implement.

- Define the goals of your project.

- Determine the path to success and measure it at each milestone.

- Explore how you can improve the project management process.

- Develop a solid plan based on the project scope and deliverables.

- Finally, launch and implement the project.

To make this methodology work perfectly, project management software can help in different ways to analyze and monitor the project data and process. With the help of the right tools, PMs and teams can collect feedback at each stage to identify the points of improvement. Users can visualize the projects using Gantt charts and can streamline the project workflow by documenting everything at a centralized location.

1. Deming Cycle

Deming Cycle is based on the philosophy of William Edwards Deming. It focuses on controlling and improving the project process continually. PCDA is followed here that refers to Plan, Do, Check, Act/Adjust.

- The Planning phase is about assessing the current project management processes and identifying the problematic areas.

- In the Do phase, PMs look for solutions.

- The Check phase is about gathering relevant information about the solutions and improving them.

- Finally, implementation of the solution is done in the Act phase.

This particular lean project management methodology works great on recurring projects.

2. Kanban

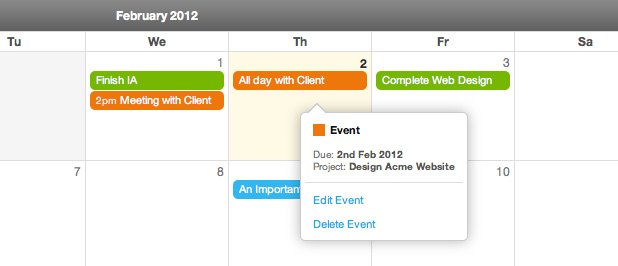

A famous methodology that involves cards and boards, is based on visual signals to improve project management. With the help of Kanban, PMs can easily visualize the project progress, track the tasks & due dates, and save a lot of time and cost.

- Visualize the project workflow.

- Limit the work in progress and manage doable tasks.

- Manage the flow of tasks according to priorities.

- Implement feedback loops to get the tasks reviewed.

- Collaborate with stakeholders for regular improvement.

The organization of work requirements becomes easier with Kanban boards and PMs can identify the bottlenecks to take them up on priority.

Principles of Lean Thinking

As the principles of lean thinking were slowly brought to the Western World, they also left the confines of pure manufacturing. By the middle of the 90s, the lean methodology would be applied to corporate management as well. A new set of best practices, tools, and management principles came into existence; that managed to improve the operational quality in corporate environments that weren’t necessarily based on retail-oriented manufacturing.

In order for a project to be considered Lean, it must use the absolute minimum in terms of space, labor, equipment, and materials, to produce the best possible results. Below, we’ll explore the core principles of this philosophy.

1. Specified Value

The most important lean principle is value specification. In other words, each service or product must have a defined and clear value; one that depends on its capability to satisfy a client at the adequate price and at the right time – both of which are defined by them. Yes, the value is in the eyes of the customer and what they expect from you. And extracting the best possible price for the value of the product is what this principle focuses on.

2. Identifying Product Value Streams

So, what is a value stream? In terms of lean management, this is the sum of every action that is currently needed to bring a product to market; from the state of raw materials to the finished product, or from a concept to the launch. The first practical thing that lean project management does is to make a map of the value stream, analyzing the worth of each step in the current process. Then, the PM proceeds to spot waste creation and produces a future-state map; one that depicts what the process should look like. After that, a plan for improvement is generated, enabling the transition from the existing plan to the one depicted in the future state.

3. Increasing Value Flow Via Waste Elimination

Once you have produced the value stream map and defined the value of the product, this step includes the insurance of a continuous flow; one that has no interruptions, reworks, scraps or backflows. Having no waste and no stoppages is the most important criteria here. While analyzing value streams, all work can generally be categorized into three types:

- Value-Added Work – These actions are deemed essential to the service or product. This is the category that brings the most customer value.

- Value-Enabling Work – This part of the flow represents actions that may be cut in the future, but cannot be eliminated in the given moment. Essentially, these are actions that are required to make the process run in its current state. Culture, environment, and technology dictate these activities.

- Non-Value Work – This is the type of action that can generally be eliminated without disrupting the workflow too much and doesn’t depend on the changing of different areas. Basically, the type of work nobody actually needs, representing complete waste. This should be eliminated on identification.

Types of Waste

Generally, we can categorize all of the above-mentioned non-value work into these types:

- Overproduction – Producing a larger amount of anything than it is needed at the given time.

- Waiting – Time spent waiting for resources and approvals, etc.

- Transportation – Time wasted in the process of transporting or delivering finished goods, parts, or materials at the end of each milestone.

- Inventory – Keeping a lot of resources occupied in advance even when they’re currently not required.

- Defects – Parts of the process that have to be reworked or repaired.

All these areas should be identified at the earliest and PMs should design the workflow by eliminating this non-value work.

4. The Client Dictates The Flow

The trick here is not delivering any value before your client actually wants it. And you definitely must not give your customers more than you initially agreed to, in terms of scope. It is achieved using the Kanban system. As discussed earlier, the Kanban system is all about boards and cards to visualize the progress of the project. PMs can manage the resources, check the status of tasks, and clients can provide feedback or approvals quickly.

5. Constantly Strive To Improve

Finally, the last step entails the constant pursuit of perfection, leading to a long-term transformation of the team into a lean culture mindset. And seeing as true perfection is unattainable, in reality this means constant process improvement. Every team member must question the merit and value of each activity in the production process to improve.

Lean Project Management Benefits

The increasing popularity of the Lean principles is due to their core values that focus on improving every aspect of the workflow and involve all stakeholders. The major benefits of lean project management are:

- Increased Efficiency & Productivity: When team members are on the right track to deliver value, their focus is on being productive as there are no distractions or unclear requirements.

- Focus: With Lean methodology controlling the show, waste reduction is the key. The workforce will be focused on tasks and activities that bring value to the organization and meet the expectations of the client.

- Smart Process (Pull System): By implementing the pull system, the team needs to deliver work only if there is an actual demand. All the unnecessary work and tasks are eliminated this way.

- Better Use of Resources: As the production is based on demand and accurate requirements, PMs can use resources and allocate tasks to the team members in a more efficient way.

- Higher Profit: Time is money and if we are wasting time, it’s a waste of money. As the lean methodology is about managing time efficiently, PMs can meet the client’s requirements faster which is very profitable.

Lean Project Management as a Solution

Let’s face it – time and money are extremely important for everyone in their everyday lives. But when it comes to manufacturing and project management; they become absolutely critical. These are two basic resources that managers have to keep in mind as they work on bringing their project to a successful conclusion. But how do you bring a hazy schedule and a shifty budget in line?

For many people, projects, and companies – lean project management was definitely the answer. A lot of studies, surveys, and conference reports suggest that about half of projects everywhere are over budget and/or behind schedule. Naturally, lean program management isn’t a magic spell that will solve all of this overnight. However, it does provide the structure needed for a disciplined approach, allowing a careful examination of each activity in the overall project lifecycle.

Many project managers from across the globe have earned the Lean Project Management certification to enhance their management skills. The certification mainly focuses on the waste reduction principles of Lean and the main objective is to ensure maximum project value. There are various institutions offering this certification and PMs can definitely boost their skillset.

To further help out in managing the projects efficiently, a Lean Project Management Software can do wonders. PMs can easily plan work and design the workflow. With the help of Kanban boards, they can track the progress of tasks, reallocate resources, and leave feedback. There are multiple options for reporting and analytics to analyze and identify the bottlenecks. Team members can work together in a collaborative environment to finish the project on time and within budget.

Frequently Asked Questions

Q. What is the lean method?

The lean method is the key factor as long as project management is concerned because it ameliorates processes and dwindles the wastage of time and resources. Basically, the lean method improves the odds of project success. With the help of it, project managers can achieve the best possible results with minimal use of available resources.

Q. How do you apply lean to a project?

If you take a look at any given project and want to apply lean management methodology to it – you start by making a clear overview of every step currently found in the process. Then, you individually evaluate these steps in accordance with the lean management principles. Once you’ve deduced which steps in the process need to be altered, cut, or retained; you can start implementing such changes. After that, you’ll be left with a project with no excess steps or resource drains – a truly lean one.

Q. How many lean principles are there?

There are five principles of lean management, each describing how one would go about introducing lean management principles in any project or work environment. While these principles were first intended to be used in manufacturing, they found their way into project management methodology as well.

Q. What is a good example of lean thinking?

Apart from Toyota which we’ve mentioned above, Intel was one of the first big companies to implement lean management principles in their production process. Seeing as they were always a giant in computer processor manufacturing, they needed to provide the market with a zero-bug product. And lean thinking allowed them to increase the quality of their products while simultaneously reducing the time to market from three months to just ten days.

Q. Why do companies implement lean?

Companies all over the world implement lean management systems because these allow them to improve; both in terms of fiscal responsibility and in terms of product quality. Lean thinking gives corporations the opportunity to increase customer satisfaction while also cutting costs.

This kind of project management isn’t just good for one specific product; if implemented over a longer period of time, it changes the corporate culture – steering it toward a constant need for improvement and extreme efficiency.

Do you want a free Project Management Software?

We have the #1 Online Project Management Software for effective project management.